Bearing Selection Flowchart

| var cpro_id = 'u3171089'; |

Recommend to friends | Comments | Close window

| Bearing Related Knowledge |

| IKO Cam Bearing Fault Cleaning Method – Detailed Analysis British Tapered Roller Bearing LM501349/10 Analysis and Handling of Bearing Faults in Cement Machinery (Part 3) Considerations in Selecting Bearing Supports SKF Bearing Division |

This article is linked to http:// Please cite China Bearing Network http://

Previous: How to Avoid Overheating of Imported Bearing Parts? Next Part: Rolling Body – Chinese vs. English Comparison and Interpretation --- Word count: 560 characters.

Best LED Tunnel Light Manufacturer and Outdoor LED Lighting Fatory in China

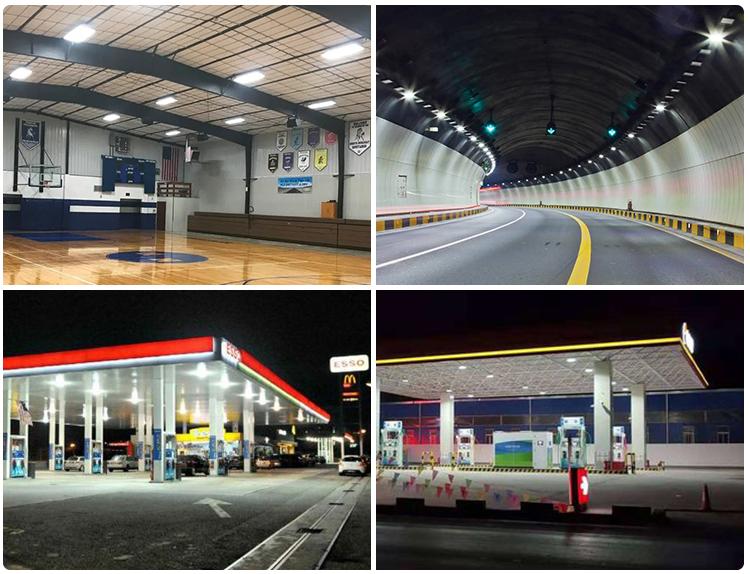

Tunnel lights are a vital component of transportation infrastructure, designed to provide consistent, glare-free illumination inside road tunnels, underpasses, mining shafts, and similar enclosed environments. Unlike general outdoor lighting, tunnel lighting must address specific challenges—such as low natural light, driver adaptation, high humidity, dust, and vehicular vibration.

As a leading manufacturer of LED tunnel lights, we offer robust, high-efficiency lighting systems tailored to meet the demanding standards of tunnel environments. With advanced optics, anti-glare lenses, and rugged housings, our products ensure safe driving visibility, reduced maintenance, and optimal energy use across long tunnel spans.

What Is a Tunnel Light?

A tunnel light is a high-intensity, wide-beam lighting fixture installed in tunnels or enclosed transit passages to ensure safe and comfortable visibility. These lights are typically ceiling- or wall-mounted in rows to provide consistent luminance levels and help drivers smoothly adapt when entering or exiting a tunnel.

Modern LED tunnel lights offer several advantages over traditional HPS or fluorescent tunnel lamps:

-

Lower energy consumption

-

Longer lifespan

-

Better color rendering and visibility

-

Instant ON/OFF with no warm-up

-

Reduced maintenance cost

Types of Tunnel Lights

| Type | Description | Applications |

|---|---|---|

| Fixed Tunnel Light | Non-adjustable, direct mount | Standard tunnels and underpasses |

| Adjustable Tunnel Light | Tiltable bracket or swivel mount | Sloped tunnels or specific beam direction |

| Linear Tunnel Light | Elongated for even lighting | Subway tunnels, corridors |

| Explosion-Proof Tunnel Light | Flameproof design | Mining tunnels, oil/gas sectors |

| Smart Dimmable Tunnel Light | Sensor or control-based brightness | Entrance, exit, or adaptive lighting systems |

Key Features of Our LED Tunnel Lights

✅ 1. High Lumen Output

Using top-tier COB or SMD LEDs, our tunnel lights deliver 130–160 lm/W for optimal brightness and efficiency.

✅ 2. IP66 / IP67 Waterproof Rating

Rugged aluminum housings with tempered glass or PC lenses, built to resist dust, humidity, and water ingress.

✅ 3. Anti-Glare & Optical Lens Design

Precise light distribution with batwing or asymmetric optics, reducing glare and driver discomfort.

✅ 4. Impact and Vibration Resistant

Tested to IK08–IK10 impact standards, ideal for tunnels with constant vehicle movement and shock.

✅ 5. Wide Voltage & Surge Protection

Compatible with AC85–265V, and equipped with 6kV–10kV surge protection for safe operation in harsh conditions.

✅ 6. Smart Lighting Ready

Support for DALI, 0–10V, PWM, or timed dimming for energy-saving tunnel lighting control systems.

Tunnel Lamp, Led Tunnel Light, Tunnel Led Light, Tunnel Flood Light, Outdoor Tunnel Light

Jiangmen Synno Lighting Co., Ltd. , https://www.synnoled.com