Nano-cubic boron nitride: the new darling of hardness beyond diamonds

2025-07-15 03:03:54

Summary According to a U.S. magazine, diamonds are no longer the hardest material in the world. In the January 2013 issue of *Nature*, an article revealed the discovery of a new material that surpasses diamond in hardness. This breakthrough was led by a research team from institutions such as the University of Chicago.

The study highlights a newly developed ultra-hard material known as cubic boron nitride (cBN), which has been engineered to outperform natural diamonds. Scientists found that this transparent material has a Vickers hardness of 108 GPa, compared to 100 GPa for synthetic diamonds. It is also twice as hard as commercial cubic boron nitride, making it a significant advancement in materials science.

What makes this material so special is its unique nanostructure. Researchers used boron nitride particles with an onion-like structure and subjected them to extreme conditions—pressing them at 15 GPa under high temperatures of 1800°C. This pressure is roughly 68,000 times greater than that of a car tire. The intense compression caused the particles to reorganize into a nanocrystalline structure, enhancing their mechanical properties.

In this nanostructured form, atoms share boundaries, much like how apartments are arranged in a building. By reducing the size of these particles, scientists were able to increase the material’s resistance to deformation. As Dr. Tian Yongjun explains, this nanostructure not only increases hardness but also improves the material’s ability to resist penetration. For boron nitride, the characteristic strength is around 4 nm, and under high-temperature conditions, the material remains highly stable.

Looking ahead, this superhard material could become a cost-effective alternative to current low-hardness cubic boron nitride. It has potential applications in various industries, including machining, milling, drilling, and cutting tools. Additionally, it may be used in the development of advanced scientific instruments, opening up new possibilities in engineering and technology.Yokelink has been supplying fasteners for the wind energy industry for over 10 years. These fasteners are utilised in producing a gearbox, a valuable wind mill turbine component located within the nacelle. we also offer standard wind power energy fasteners in line with ISO or DIN, including vibration-resistant security products. Wind tower bolt plays a important role as joining components in fastening different parts of wind turbine tower, Yokelink is a professional manufacturer which supplies high grades fasteners 8.8-12.9 for wind tower projects.

Product Ranges:

We currently service all aspects of the wind turbine market, Our extensive range allows wind

turbine manufacturers to 'single source'all their fastener requirements with all the advantages that this brings, providing a range of fasteners, both standard and customer bespoke for:

turbine manufacturers to 'single source'all their fastener requirements with all the advantages that this brings, providing a range of fasteners, both standard and customer bespoke for:

â—Foundation

â—Tower Construction

â—Blade to Hub

â—Nacelles

â—Off-shore Transition Pieces

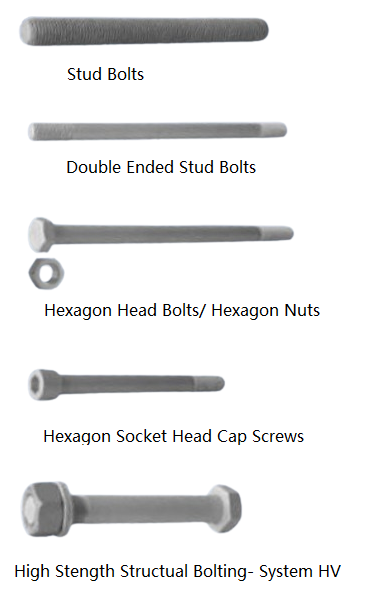

Hex cap screws DIN 931, DIN 933 and ISO 4017

Hex Bolts and Nuts, size M10-M64

Stud Bolts size M12-M64

Threaded Rods size M10-M64

Tower Flange Bolts size M10-M64

WHAT ARE WINDMILL POWER FASTENERS?

WHAT ARE WINDMILL POWER FASTENERS?

Fasteners used in wind power tower and blade connection and transmission, including hex bolts, stud bolts, tower flange bolts, foundation bolts, threaded rods, high strength double head screw, hardened and structural bolts, nuts, washers and threaded rods, and hex cap screws etc.

WHAT'S THE CHARACTERISTICS OF WIND POWER FASTENERS

High strength, high grade and precision, can work in hard conditions like extremely hot and cold environment and corrosion resisted .In wind turbine generator system, because of the randomness of power source, hardness of operating circumstances, special producing and installing, as well as high costs of maintaining, the requirements for wind turbine bolts would be extremely high. We have to take effective actions to ensure the reliability of the bolts connection, from the bolts structure design, manufacture process to production and assembling.

WHAT BOLTS ARE USED IN A WIND TURBINE?

Wind turbine bolts, there are wind turbine blade bolts, wind turbine anchor bolts, wind turbine foundation bolts, high strength and high tension hexagon head bolts, nuts and washers are mainly used for wind turbine.

HOW MANY BOLTS ARE IN A WIND TURBINE?

A most common 3 blades wind turbine requires almost 25,000pcs fasteners. With the rapid increase of wind energy demand in the worldwide, the fasteners for wind turbine and energy increased greatly as well. Most high strength bolts used for wind turbine are grade 10.8, grade 12.9 and the coatings are also very crucial, Dacromet are most commonly coating in wind turbine fasteners.

A most common 3 blades wind turbine requires almost 25,000pcs fasteners. With the rapid increase of wind energy demand in the worldwide, the fasteners for wind turbine and energy increased greatly as well. Most high strength bolts used for wind turbine are grade 10.8, grade 12.9 and the coatings are also very crucial, Dacromet are most commonly coating in wind turbine fasteners.

When you need Wind Power Fasteners, refer to above our catalog. We offer them in a full selection of sizes, provide the diameter or part number to get a quote of wind power fasteners, leave your message, or send us an email. You can also call us to get answers to your questions and place your order.

Wind Energy Fasteners Supplier China, Yokelink

sales@yokelink.com

Wind mill ,Wind Power fasteners, Wind mill Turbine, Stud Bolt, windmill energy, house wind turbine, Wind Turbine Blades

Ningbo Yokelink Machinery Co.,Limited , https://www.yokelink.com